Batch Procedure Module

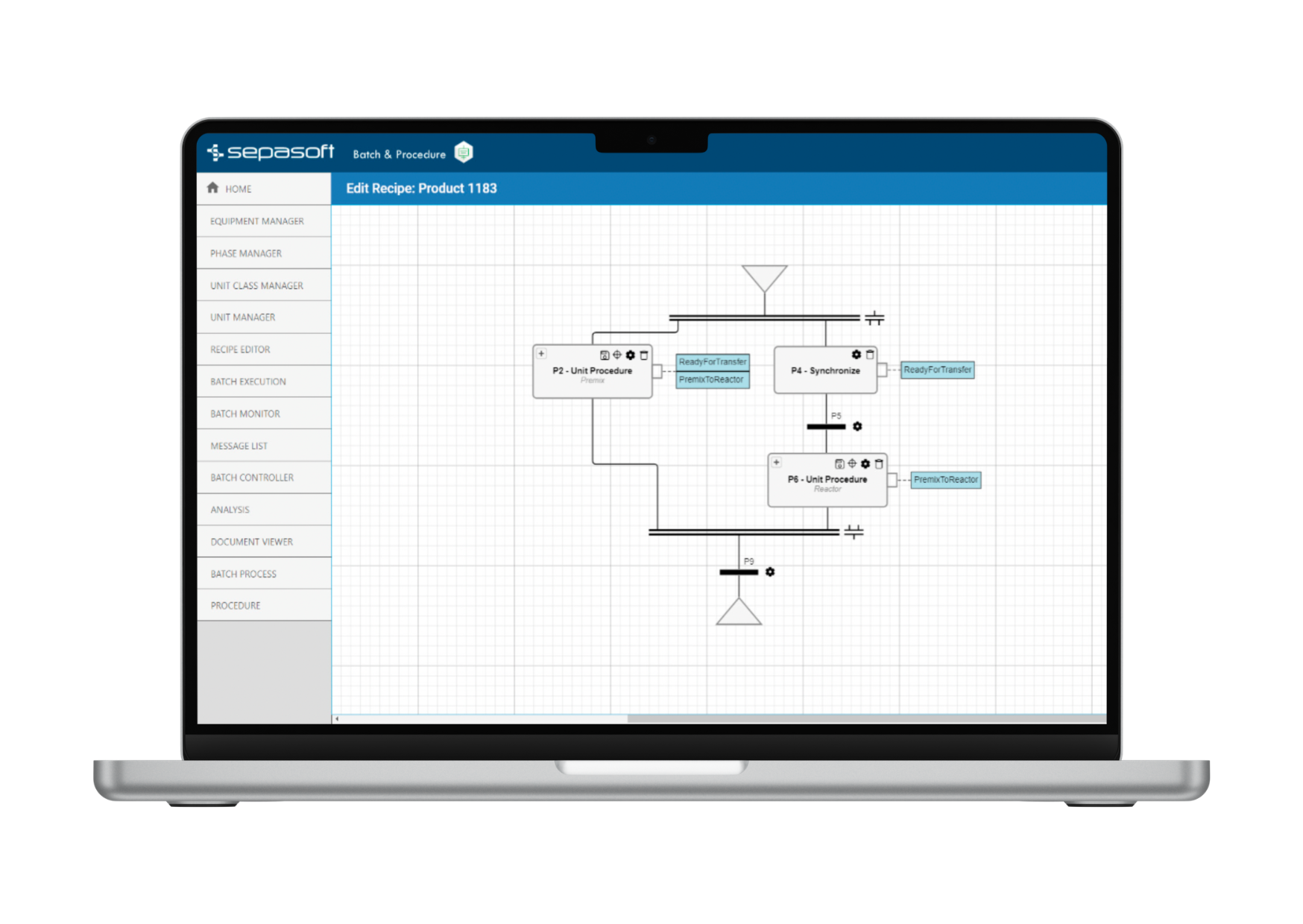

Graphical recipe editor

Easily edit recipes on a single user-friendly screen using modern drag-and-drop technology. With less system training and development work required, recipe writers and operations staff can focus more easily on the product.

Separation of recipes and equipment control

Provide recipe writers and control system engineers with the opportunity to specialize in their independent roles. By separating recipes from equipment control, engineering and training costs are reduced throughout the entire lifecycle of the production process.

Key features of the Settings & Changeover module

Golden batch comparison

Focus on the optimal recipe (“Golden Batch”) by examining which factors led to the most successful result. With access to large quantities of high-quality data, both effective processes and problematic events can be traced back to specific batches.

Real-time batch status

Enable operators to easily check the status of a batch without an SFC chart. With less navigation and drill-down required to check a batch, operators can focus on production.

Batch procedure use cases

Manage ISA-88 batch processes, production procedure-driven workflows, and hybrid processes in one toolset. Simplify maintenance and reduce total ownership costs with a unified solution that easily fits into various protocols and workflows.

Built-in User Defined Type (UDT) interface

Streamline configuration and minimize errors with access to a built-in UDT interface. Map a UDT once for field equipment, and each instance of this UDT will be automatically configured.

Dynamic dashboards

Share meaningful information using real-time dashboards tailored to your business needs.

No-nonsense licensing

As the organization grows, scale the batch system without needing to purchase additional capacity. Users, screens, reports, and connections to field equipment are unlimited within a site license.

Best-in-class HMI

The Batch Procedure module is one of the few solutions with an integrated HMI. Unlike alternatives, there’s no need to separately purchase an HMI solution or map tags in a custom API.

Multiple transfer methods

Choose from multiple material transfer methods that best suit existing field equipment. With the ability to run different recipes on each unit, the Batch Procedure module easily adapts to the organization’s existing processes.

Elektronic signatures

Promote accountability and compliance within the production process by demonstrating approvals with electronic signatures. Include any number of electronic signatures from different roles in the batch recipe to ensure approvals are properly documented for historical record.

Elektronic batch records

Ensure critical procedures are followed and automatically documented to demonstrate the results of each process step. These data are stored in electronic batch records and easily viewed alongside quality and traceability documents.

Easy ad-hoc analysis

Identify the source of quality issues and inconsistencies with customizable ad-hoc analyses, allowing users to select unique combinations of data values, filters, groups, and orders. Analyze unlimited amounts of historical production data to identify trends and implement successful practices into future operations and schedules.

User-defined batch parameters

Create custom parameters to accurately represent your organization’s batch process. Define tag type, custom calculations, data types, minimum & maximum values, and more.

Reusable templates

Unit procedures or operations can be templated and reused for faster and simpler recipe development. This functionality reduces time spent on avoidable and repetitive configuration tasks.

Production data sync for multiple sites

Improve visibility and reliability across the enterprise by easily sharing schedules, production results, and more across multiple locations and servers. Thanks to the ready-made functionality, integration work and custom coding are significantly reduced.

Document management

Safely and easily manage production-related documents to make complex manual processes more repeatable and consistent. Create and distribute documents that operators can fill in and save with batch data for historical records. Learn more about Document Management module.

IIoT/MQTT functionality

Prevent loss of historical data, optimize network bandwidth, and enhance security by leveraging IIoT, with built-in MQTT and OPC/UA support.

Custom parameter calculations

Accommodate your organization’s custom requirements in batch parameters with dynamic calculations. Calculate ingredient quantities based on concentration, determine mixing time based on humidity or temperature, and much more.

Simplified validation process

Simplify compliance validation using built-in tools like version control and a detailed change log to address specific validation areas rather than revalidating the entire process. All changes to batch configuration are automatically logged in a complete audit trail, including location, date, type of change, responsible person, and more.

SCADA/HMI integration

Save hours of customization by managing MES, SCADA, HMI, and more on one platform with a unified operator interface and design tools.

Sync with ERP systems

Connect to your ERP or higher-level business system without custom development or the burden of maintaining large amounts of scripts over time. Complex scripts are replaced by a user-friendly visual interface to monitor communication and map data between systems.

Discover Ignition

your way

Start building

For developers

Get started with your own Ignition applications right away.

- Download and install Ignition easily and quickly.

- Explore all features.

- Connect unlimited tags, PLCs, databases, and devices.

Discover how Ignition solves your technical challenges without limitations.

See Ignition in action

For managers

Explore Ignition without any technical knowledge in the demo environment.

- No installation required.

- See how Ignition automates and visualizes processes.

- Adjust live values and see instant results.

Experience real-time automation and discover what it can offer your business.

Want to really know what Ignition can do for you?

Let us come to you for a free demo.

- Meet with our experts and ask all your questions.

- Get personalized advice.

- See how Ignition can optimize your processes.

The perfect opportunity to collaborate with specialists and see exactly how Ignition can help you achieve your business goals.