OEE Downtime Module

Maximize production efficiency with OEE Downtime

Tracking Overall Equipment Effectiveness (OEE) and downtime has become easier. This module enables manufacturers to reduce operating costs while increasing asset utilization and operational efficiency. This results in improved profitability.

Real-time efficiency tracking

With the OEE Downtime module, you gain immediate access to current production, efficiency, and downtime data through graphical and operational dashboards. This enables management and operations departments to respond immediately to issues occurring today, not next week. Achieve continuous improvement, as well as LEAN and Six Sigma business strategies, through efficient and clear communication across all departments.

Key features of the OEE Downtime module

Downtime data collection

The OEE Downtime module supports automatic and manual collection of downtime reasons, or a combination of both. Visually identify the top downtime reasons and address those impacting your operational efficiency.

Instant dashboards at a glance

Quickly organize and visualize efficiency and downtime data across your entire organization with powerful analysis tools that show more than traditional standard reports.

Seamless Enterprise Resource Planning (ERP) integration

This module is IT-friendly, allowing seamless communication within the entire organization, enabling integration with ERPs and other applications to share data.

Mobile MES access

Access OEE reports from your mobile device. Save production workers time by allowing them to enter downtime reasons and production schedule changes directly.

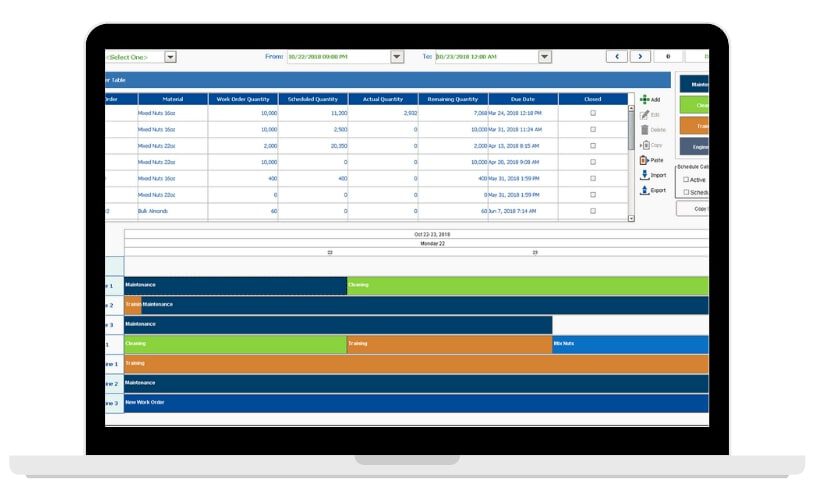

Production scheduling

All departments within the company have instant access to current production, maintenance schedules, and more. Prevent miscommunication by modifying the schedule and improving overall workflow and efficiency.

Fully customizable

Because every manufacturer has different requirements, this module allows you to customize existing screens, reports, calculations, etc. You can also create a fully customizable system from scratch, giving you full control over your data.

Work order management

Track real-time work order status showing planned production, produced production, and remaining production. Manage product codes, production rates, packaging sizes, and more.

Automatic data collection

Improve data accuracy with automatically recorded data instead of manual entry and interpretation by production workers. As an added benefit, those valuable hours can be utilized elsewhere.

Discover Ignition

your way

Start building

For developers

Get started with your own Ignition applications right away.

- Download and install Ignition easily and quickly.

- Explore all features.

- Connect unlimited tags, PLCs, databases, and devices.

Discover how Ignition solves your technical challenges without limitations.

See Ignition in action

For managers

Explore Ignition without any technical knowledge in the demo environment.

- No installation required.

- See how Ignition automates and visualizes processes.

- Adjust live values and see instant results.

Experience real-time automation and discover what it can offer your business.

Want to really know what Ignition can do for you?

Let us come to you for a free demo.

- Meet with our experts and ask all your questions.

- Get personalized advice.

- See how Ignition can optimize your processes.

The perfect opportunity to collaborate with specialists and see exactly how Ignition can help you achieve your business goals.