SPC Module

Automate SPC data collection and enhance quality analysis

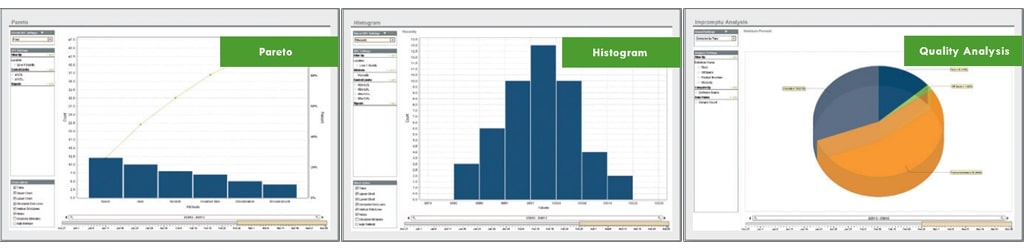

Ensure that Statistical Process Control (SPC) data is accurately and timely collected with the SPC module. SPC assists in reducing or eliminating late or missing sample collection, inaccurate sample data, or other issues leading to quality problems. Deliver your SPC data in real-time to the right people in a comprehensive format using flexible control charts and analysis tools.

Increase accuracy and prevent late SPC samples

Taking accurate, regularly scheduled samples is essential to maintaining quality. That’s why we’ve made it easy to automatically schedule samples in real-time using the SPC module. You can take samples based on actual production conditions and utilize convenient, automated alerts to ensure samples are never missed. Customizing a sampling schedule is straightforward and entirely flexible, allowing you to meet the requirements of your unique production environment.

Key features of the SPC module

Automatic alerts for out-of-control conditions

To ensure quality, it’s crucial to keep processes within acceptable control limits. This is achieved by identifying out-of-control variations as quickly as possible without human intervention. The system automatically alerts you when an out-of-control condition or bogus sample data is detected. Alerts are easily customizable, allowing you to configure the module to send email or SMS notifications, flash a screen indicator, halt production, or apply a variety of other alerting methods. Each time a sample is taken, this module evaluates for out-of-control conditions and automatically notifies you if they are present. With SPC, you can quickly identify and address runaway variations before they become a larger issue.

Customize charts

All the data in the world is meaningless without proper analysis tools, which is why we built this module with a full suite of powerful and flexible SPC control charts. Based on security roles, control limits can be calculated and interactively set on the control charts. The “additional factors” feature gives you the flexibility to associate and visualize other production information alongside SPC data. With customizable display settings for charts, tables, control limits, and signals, you have the ability to see the information you need, how you want it.

Connect to virtually any device

SPC data can come from various sources. That’s why this module comes with the tools you need to collect them. Built with support for automatically collecting data from PLC devices, OPC devices, laboratory instruments, RS232 devices, USB devices, data files, web services, and external databases.

Experience the

power of

Ignition

Schedule an exclusive on-site Ignition demo

- Discover how Ignition can be tailored to meet your specific business needs.

- Get answers to all your questions directly from our masters.

- Receive customized advice and solutions that can be immediately implemented.

Start building your own Ignition application

- Install quickly and effortlessly to get started right away.

- Explore the full functionality and determine if Ignition can solve your challenges.

- Connect to tags, PLCs, databases, and devices without limitations.Quick and effortless to install.

Explore Ignition in the online demo environment

- No downloads or installations needed— start exploring immediately.

- See how Ignition automates and visualizes processes without requiring programming skills.

- View applications for various industries and adjust values to see instant results.

Just one step away

Schedule your no-obligation appointment now and take the first step towards a future where your production processes are optimized, costs are reduced, and your efficiency is elevated. Discover firsthand how Ignition can address your specific challenges and help you achieve your business goals.

Don’t wait any longer, master your growth with Ignition!

No obligations – just an introductory meeting

Almost yours

No worries – we’ll assist you through the installation process

Almost there

You’re just one step away. Fill in your details to get immediate access (via email) to Ignition’s online demo environment.

Don’t wait any longer, master your growth with Ignition!

Get started instantly – no download required