Track & Trace Module

Product tracking, real-time inventory management, and operational management tools

Tracking and tracing are the processes through which manufacturers obtain and record crucial information about where and how products are made. This module automates this process and has become a modern necessity for manufacturers as their industry faces increasing economic and regulatory challenges.

Connect with production data

This module does more than track products during the manufacturing process. It gathers production information from various sources, including OEE, SPC, Settings & Changeover, and historical trends. It can also be used to retrieve data from ERP systems. The module provides navigation and linking of internal and external data to each other, all in an easy-to-understand visual representation. Moreover, it enables every enterprise to standardize its system across multiple facilities.

Key features of the Track & Trace module

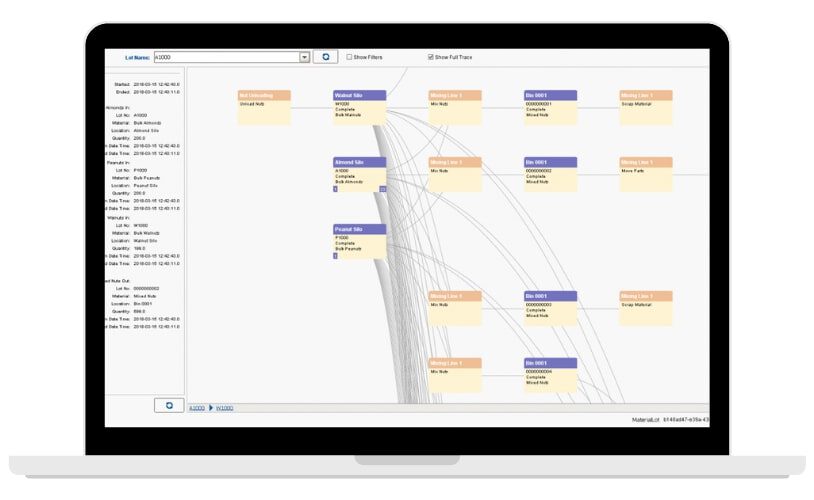

Visual trace graph

With the Track & Trace module, you can search for product information using a unique and easy-to-navigate Trace Graph display. The trace graph visualizes your search results with raw materials on the left, manufacturing processes in the middle, and finished products on the right. It allows you to see all processes, runs, batches, and routes that each product has gone through. All this information is chronologically organized and displayed in one place, making it easy to find the exact information you need.

In-depth data and analysis

This module brings together OEE, SPC, ERP, Settings & Changeover, and trend information, providing you with unprecedented accessibility. Quickly obtain action summaries, view trends within an MES application, and search within external systems such as ERPs or warehouse management systems. Identify correlations between efficiency and quality, monitor historical trends, and access compliance-related information. The variety of valuable data provides you with greater insight to make better decisions.

Paperless tracking

Track & Trace enables manufacturers to transition from the outdated practice of capturing traceability information on paper. Instead, you can store information alongside the rest of your system data on a unified platform where you can easily analyze and retrieve it. In addition to manually entered tracking, automated tracking significantly increases accuracy, speed, and efficiency.

Compliance with traceability regulations

Certain industries face increasing regulatory demands for traceability information. This module helps enterprises trace their products through the supply chain and avoid penalties by providing quick access to traceability information requested by government agencies.

Aligned with ISA-95

This module is designed to align with ISA-95, the international model for integrating business and control systems. ISA-95 provides an excellent starting point for successfully implementing interfaces between business and control systems.

Experience the

power of

Ignition

Schedule an exclusive on-site Ignition demo

- Discover how Ignition can be tailored to meet your specific business needs.

- Get answers to all your questions directly from our masters.

- Receive customized advice and solutions that can be immediately implemented.

Start building your own Ignition application

- Install quickly and effortlessly to get started right away.

- Explore the full functionality and determine if Ignition can solve your challenges.

- Connect to tags, PLCs, databases, and devices without limitations.Quick and effortless to install.

Explore Ignition in the online demo environment

- No downloads or installations needed— start exploring immediately.

- See how Ignition automates and visualizes processes without requiring programming skills.

- View applications for various industries and adjust values to see instant results.

Just one step away

Schedule your no-obligation appointment now and take the first step towards a future where your production processes are optimized, costs are reduced, and your efficiency is elevated. Discover firsthand how Ignition can address your specific challenges and help you achieve your business goals.

Don’t wait any longer, master your growth with Ignition!

No obligations – just an introductory meeting

Almost yours

No worries – we’ll assit you through the installation process

Almost there

You’re just one step away. Fill in your details to get immediate access (via email) to Ignition’s online demo environment.

Don’t wait any longer, master your growth with Ignition!

Get started instantly – no download required