From data to valuable insights

In brief

About Agristo

The challenge at Agristo

Agristo has plans for the future and aims to embrace the ongoing digital transformation. The first step in this process is to collect reliable data, including factual and accurate information. Despite already using the Ignition platform, which enabled the company to obtain a lot of data, essential context was lacking. For example, while they could see the temperature of each sensor and the speed of the motor, it wasn’t clear afterwards which type of fries had been produced, how long an order lasted, or which potatoes were used. In short, more background information was needed alongside the collected data.

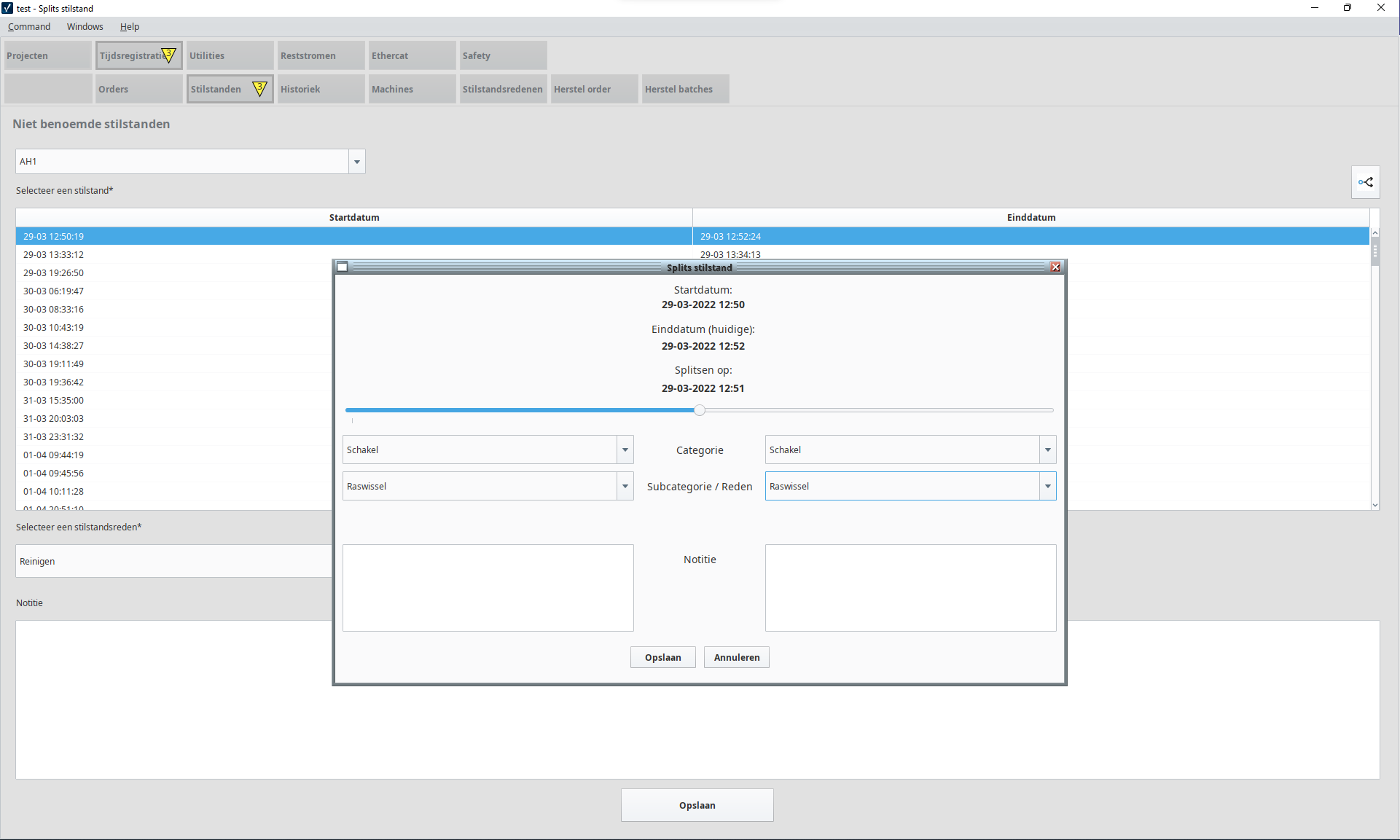

As part of their digitization efforts, Agristo also wanted to eliminate the manual paper-based process of recording when and why a production line was down. This process was highly error-prone and time-consuming. Agristo sought a streamlined, error-free transition to a digital working environment.

“AT-Automation has provided us with valuable insights into our production process, allowing us to work more efficiently without making significant modifications to our machines. The data delivered was essential for our digital transformation and growth.”

Tine Vandekerckhove, Agristo

A customized solution

A customized solution

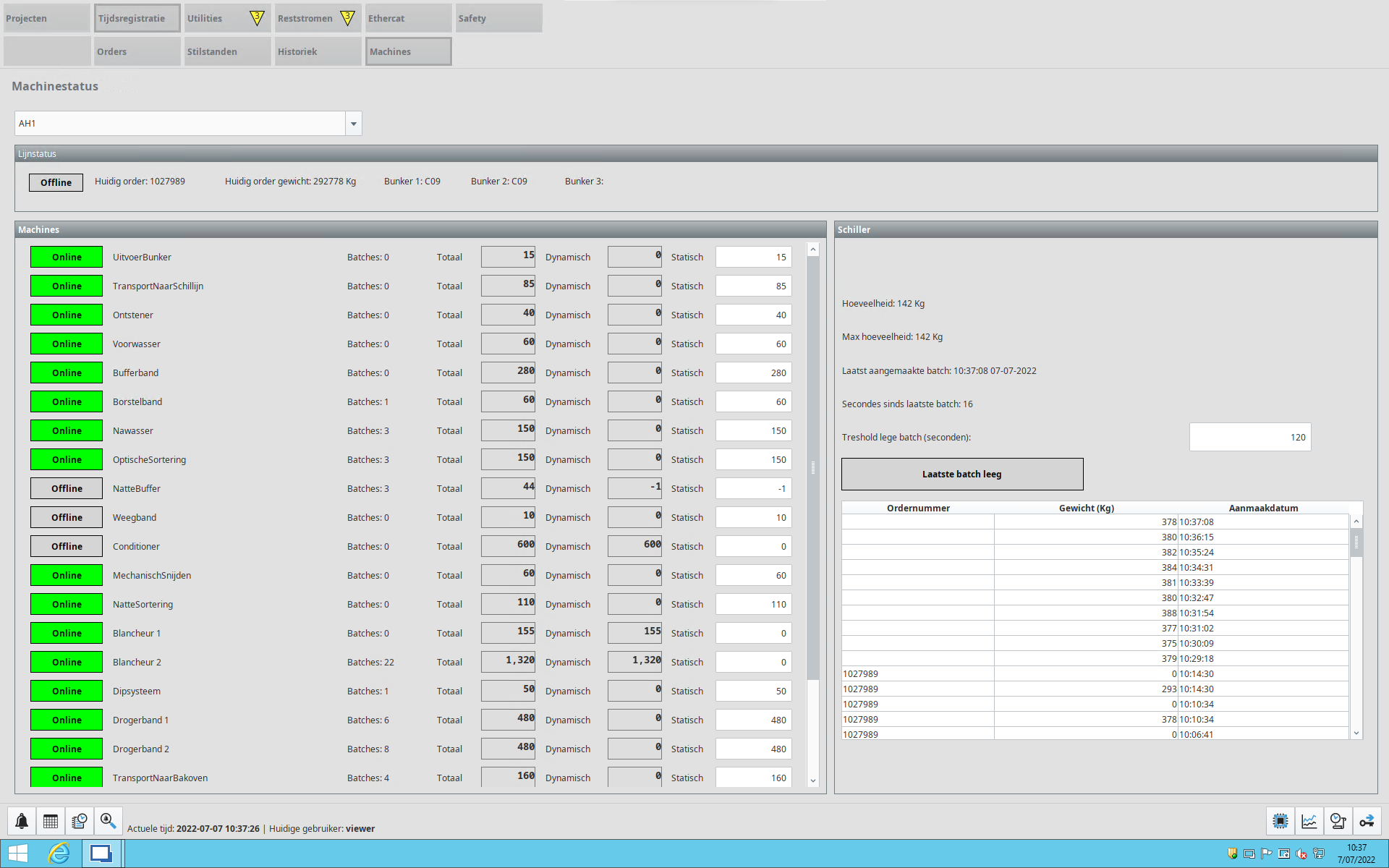

To provide more context to the existing data, we built a mini-MES application on the Ignition platform. This application not only registers every order but also provides detailed information about batch start and stop times, raw material usage, and automatic downtime registration.

Currently, Agristo is in the rollout phase of this innovative solution to other production locations. Special attention has been given to the production line in Nazareth, where specialties such as potato croquettes are produced, requiring some adjustments to the application. The timeline is ambitious: by the end of the year, all production locations should be fully operational.

While the final outcome has not yet been achieved, interim successes are already visible. By collecting all production data centrally, Agristo can link information and generate better insights. Automatic registration has improved reporting and ensured that every production location consistently and immediately records downtime.

For Agristo, this means more than just efficiency; it also means better analysis and growth opportunities. In the long term, the company aims to apply machine learning for even deeper insights into the production process. Ruben Devos of Agristo emphasizes the significant results achieved by AT-Automation with just a few simple adjustments, enabling Agristo to confidently embrace the digital future.

Tine Vandekerckhove, Agristo

Ready to master your growth?

At AT-Automation, we aim to accelerate your growth and reach new heights of efficiency with our advanced automation solutions. We strongly believe in sharing knowledge and empowering individuals to become masters in industrial automation. Would you like free advice on how our solutions can help your business grow? Please leave your contact information below.