Prevention is better than cure

In brief

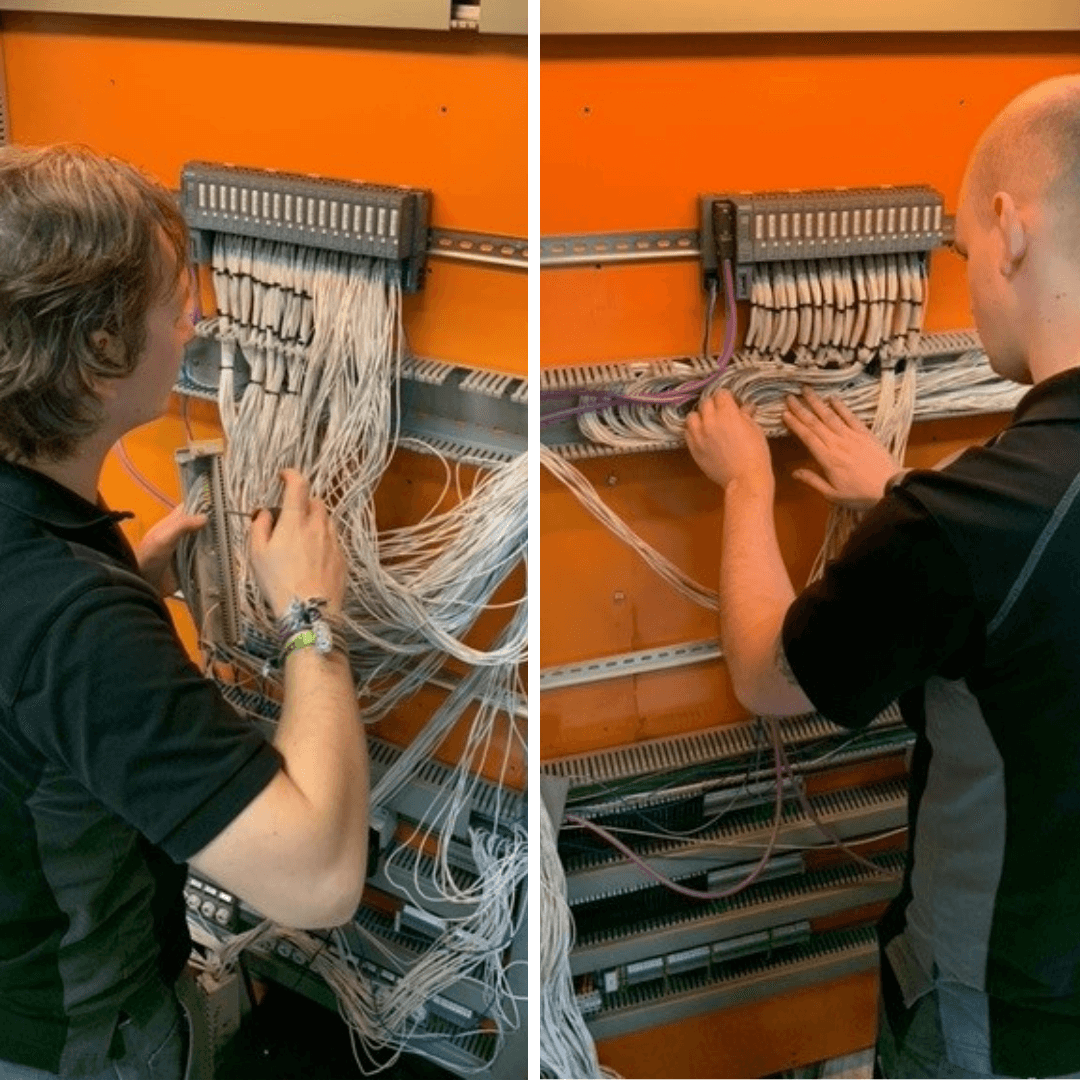

The collaboration with AT-Automation continues with the implementation of Ignition, replacing the outdated PLC control software.

About Jan de Rijk Logistics

The challenge at Jan de Rijk Logistics

Jan de Rijk Logistics was faced with a challenging situation, operating on outdated PLC hardware that was nearing its end-of-life status. The risk of reduced support and potential downtime of the automated high-rise system was a concerning prospect. The company wanted to take proactive measures to prevent customer disruption and actively sought a partner who could address the complete package: both hardware and software.

“AT-Automation emerged as a larger, more stable company with the necessary knowledge and expertise on both fronts. Compared to other options, AT-Automation offered the most accommodating and driven solution.”

Rogier Heeren, Jan de Rijk Logistics

A customized solution

A customized solution

Jeroen Lauwen from Jan de Rijk Logistics noted that this accelerated conversion was only beneficial for their company. After more than a month of using the new PLC control, Jan de Rijk Logistics has not experienced any disruptions. The system operates in the same reliable manner, but now with upgraded hardware.

Since the existing PLC control software is also outdated, it was decided to continue the collaboration and transition to Ignition.

Rogier Heeren, Jan de Rijk Logistics

Ready to master your growth?