Proactive yeast management

with telemetry

Ignition IIoT optimizes the yeast inventory and streamlines bakery production

In brief

AB Mauri was in search of an efficient way to manage yeast inventories at bakeries to prevent delays and production shutdowns. In collaboration with AT-Automation, a telemetry solution with Ignition was developed.

About AB Mauri

Meet AB Mauri, a division of Associated British Foods (ABF). With over 150 years of experience, 52 factories, and sales offices in more than 100 countries, AB Mauri is one of the world’s largest producers and suppliers of liquid baker’s yeast and bakery ingredients.

The challenge at AB Mauri

Bakeries themselves are responsible for managing their yeast inventory, an essential ingredient for bread production. In the past, it was common for bakeries to notice this too late, resulting in delayed deliveries and halted production.

At AB Mauri, fully supporting the customer is one of their priorities. The company aims to have insights into the yeast inventories of bakeries so that it can proactively contact them and plan new deliveries before the inventory runs out.

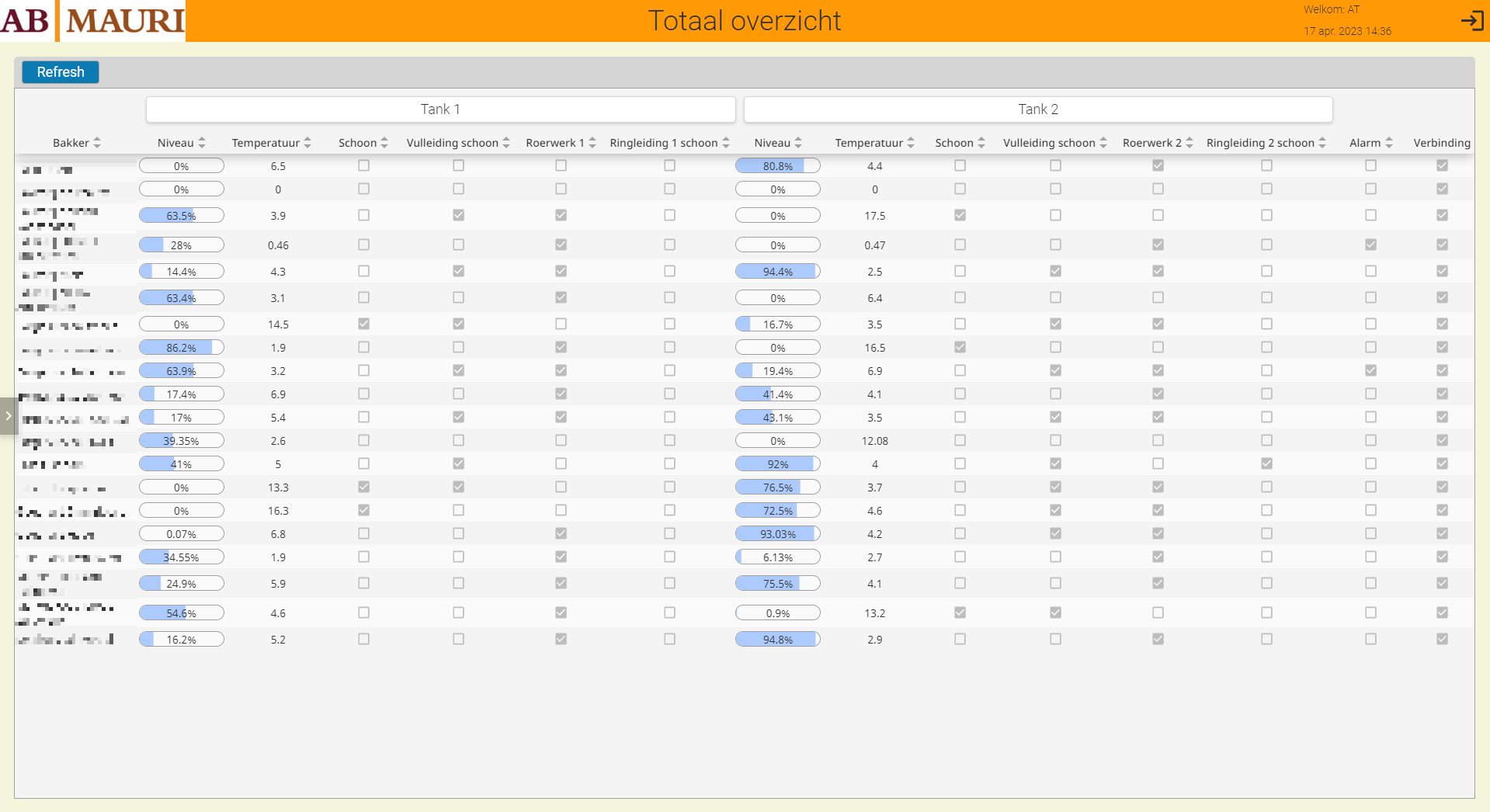

Using this data, a forecast can be created, leading to efficient transport planning for both the bakeries and AB Mauri. For example, if deliveries are planned for bakeries X, Y, and Z next week, the most ideal route can be determined, such as bakery Z, X, and Y. This enables AB Mauri to efficiently determine the routing, which is especially relevant given the current high transport prices.

Kevin Tang, AB Mauri

A customized solution

A customized solution

AB Mauri approached AT-Automation to brainstorm solutions, resulting in a telemetry solution combined with Ignition. PLC data or load sensor readings are collected via an industrial PC and sent to the AB Mauri server using the MQTT protocol. Ignition retrieves this data and visualizes it in a web application.

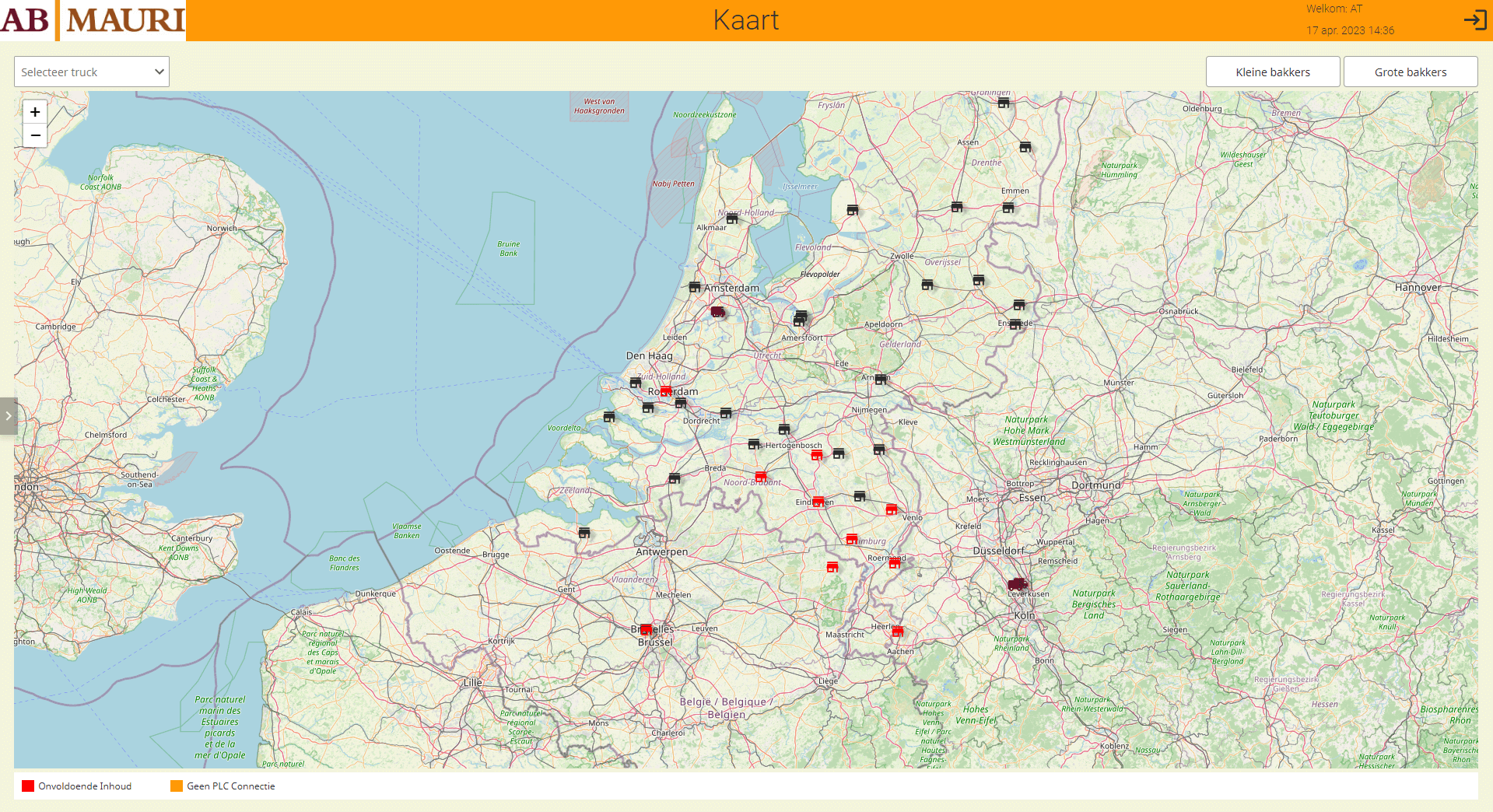

The implementation of telemetry with Ignition enables AB Mauri to remotely and in real-time view tank levels at bakeries from any device. This valuable information allows AB Mauri to proactively and efficiently plan new deliveries.

Bakeries can track the exact location of trucks via the application, including the route and the bakeries to be serviced along the way. This real-time insight enables AB Mauri to constantly update bakeries on the status of yeast deliveries.

The application, designed in the AB Mauri brand style, logs various data such as temperature, content, and CIP data, which are crucial for compliance with food and drug regulations. Users do not need to install Ignition, as the application is web-based and accessible via a URL on any device with a web browser.

Kevin Tang, AB Mauri

Ready to master your growth?